Portfolio (2014 to Present)

Fortify Inc., Boston

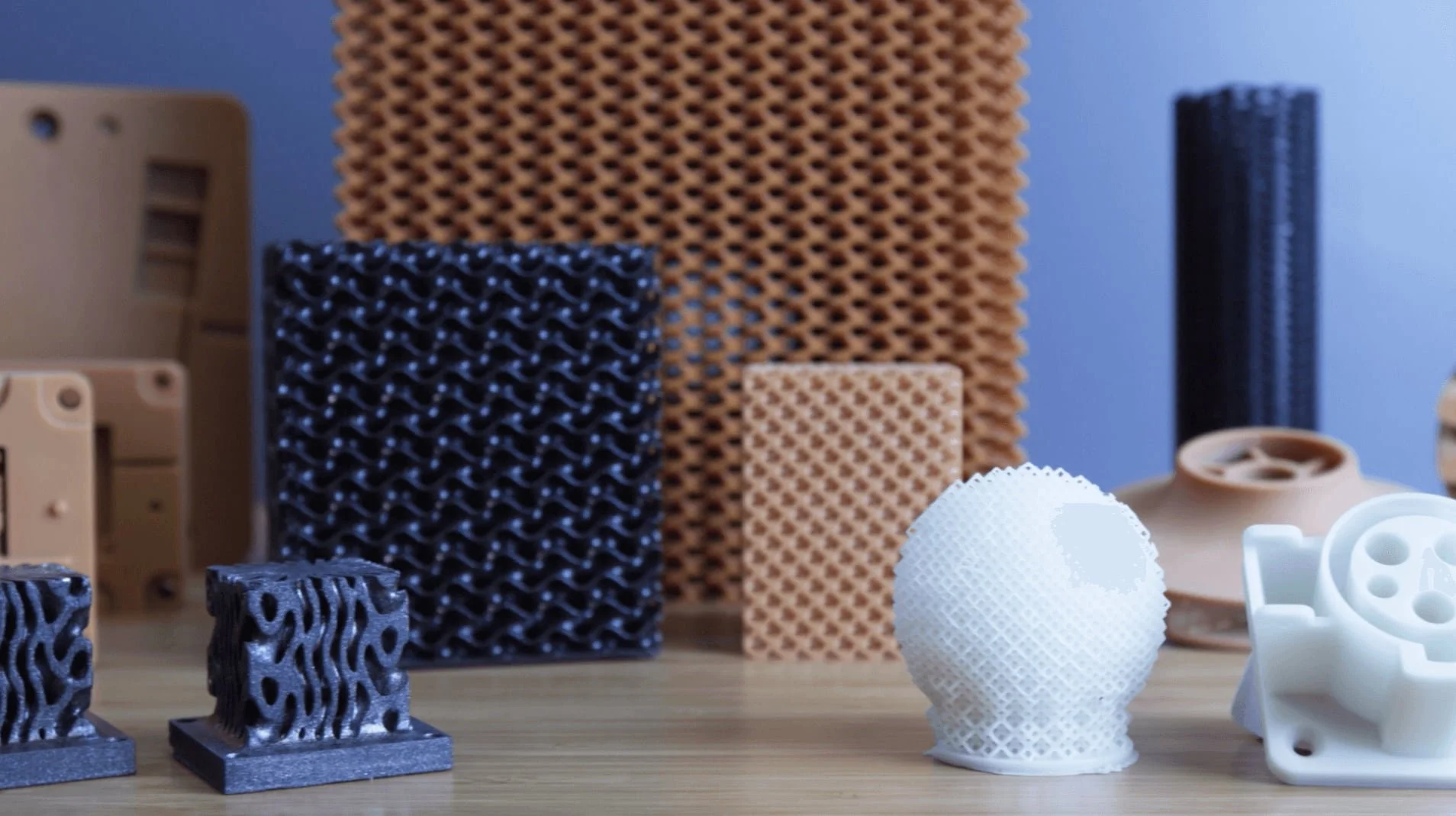

Fortify make high-end SLA 3D printers. My engagement with them began in 2021 and ran for two years, 99% remotely, initially to temporarily fill in for their Senior EE who was soon to depart the company, until a new hire came onboard, but was later expanded to assist the new hire with further re-engineering efforts.

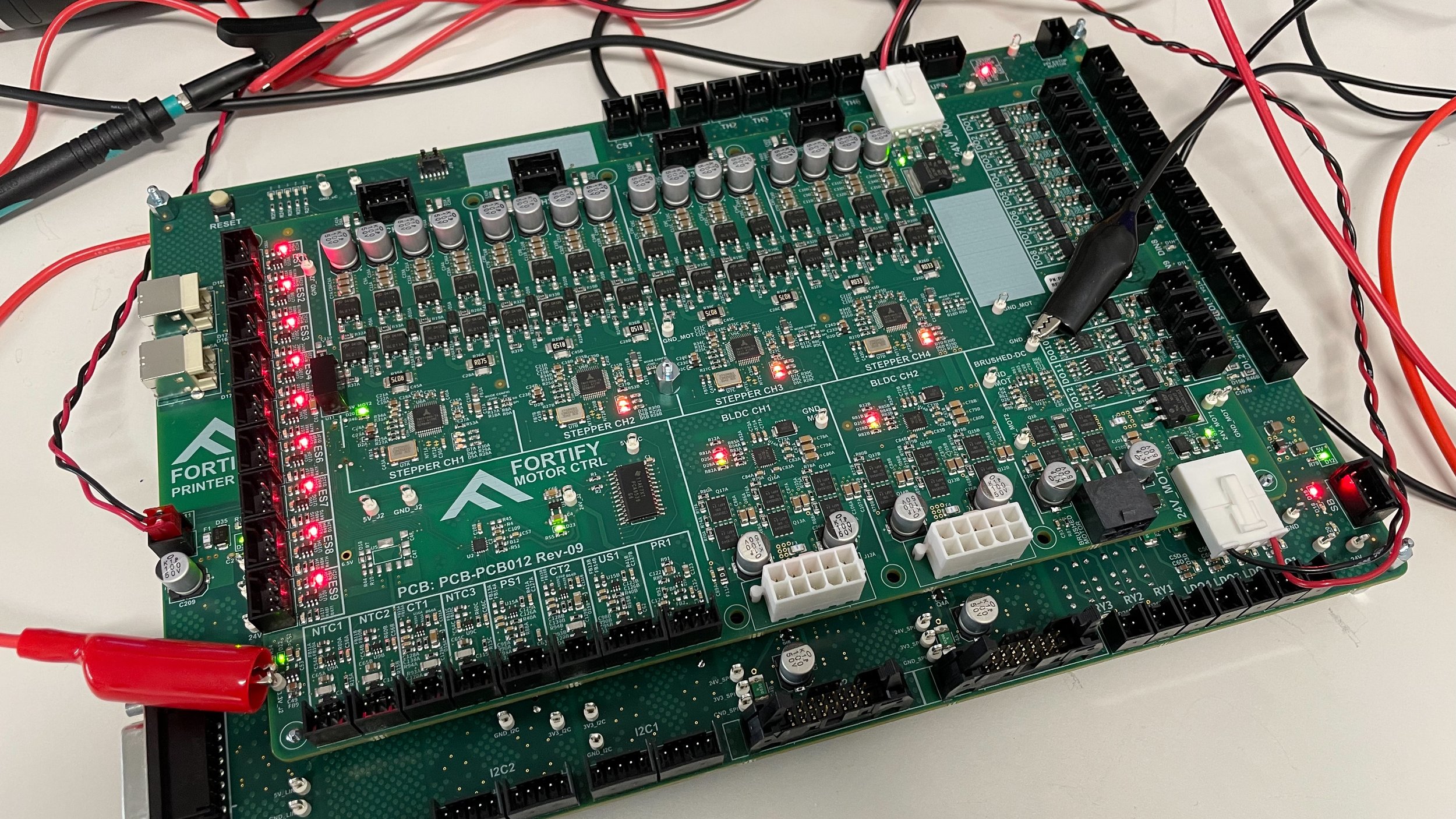

The printer’s custom electronics include seven BLDC, stepper, and brushed-DC motors/drivers, myriad digital I/O connected to 3rd-party peripherals, precision 24-bit load-cell, and a 48V/100A/5kW H-bridge driving a massive electromagnet. Over 2 years and 2 revisions to all 6 PCBs in the system, either alone or eventually under the management of their new Senior EE, major achievements included:

architected a safe & non-destructive Emergency Stop system to comply with UL requirements

discovered a silicon bug in the H-bridge controller chip, & redesigned with a new controller chip

fixed numerous hardware errors & TODOs in earlier PCB revisions

paid off a lot of technical debt & reduced power domain & galvanic isolation complexity

reviewed and designed for EMC-compliance at the system-level and PCB-level ready for imminent EMC pre-compliance testing for US & EU markets

dramatically increased manufactured PCB/PCBA yield & reliability

survived the 2021-2023 Great Electronics Supply Chain Debacle while maintining needed production volumes

assisted with the recruitment of a second Snr EE, including being on-site in Boston for their orientation and hand-over

Alloy Product Development,

San Francisco

Alloy Product Development is a boutique product development consultancy in San Francisco, providing Mechanical & Electrical/Hardware Engineering, often collaborating with industrial design agencies like Ammunition and Box Clever.

Almost everything I did/do at Alloy (while employed 2018-2020, and subsequently as a consultant) was & remains under NDA coverage - very frustrating! - so I’m unable to discuss or show virtually anything, other than to say it spanned an incredible range of consumer & wearables, commercial, and medical products for some of the most well-known global brands through to tiny start-ups.

Mavrx, San Francisco

Airborne Multi-Spectral Multi-Camera Prototype

Mavrx was a Silicon Valley tech start-up in Precision Agriculture via aerial multi-spectral imagery, helping farmers do more with less and see what can't be seen with the naked eye, providing valuable timely analytics on crop performance.

This ugly beast of a camera prototype took form astonishingly quickly (Jan-May 2016) which happens when you work Silicon Valley tech-start-up hours, but also by leveraging the Apertus open-source cinema camera design, which was based on the Xilinx Xynq 7020 FPGA-SOC, CMOSIS 12Mp Global Shutter image sensors, then 3 such cameras linked via 1Gb Ethernet to an Odroid XU4 SBC, & a ‘glue PCB’ to bind it all together - hackety-yack!

What can I say; the hardware worked! However the camera software was another matter, plus a range of business operational failures, plus a failed management coup, plus a CEO who rejected not one, but two Series-B funding offers because they were contingent on him no longer being the CEO -> company cratered 💥 2018, sold for assets value to Taranis.

That HBO TV series ‘Silicon Valley’ - it aint a comedy, it’s a documentary.

Ecoult Energy Storage Systems, Sydney Australia

Ecoult commercialised the Australian CSIRO-invented UltraBattery, a hybrid ultra-capacitor and Lead-Acid battery, providing high dis/charge rates and long-term partial state-of-charge operation, catapulting ancient Lead-Acid to be competitive with Lithium-based chemistries.

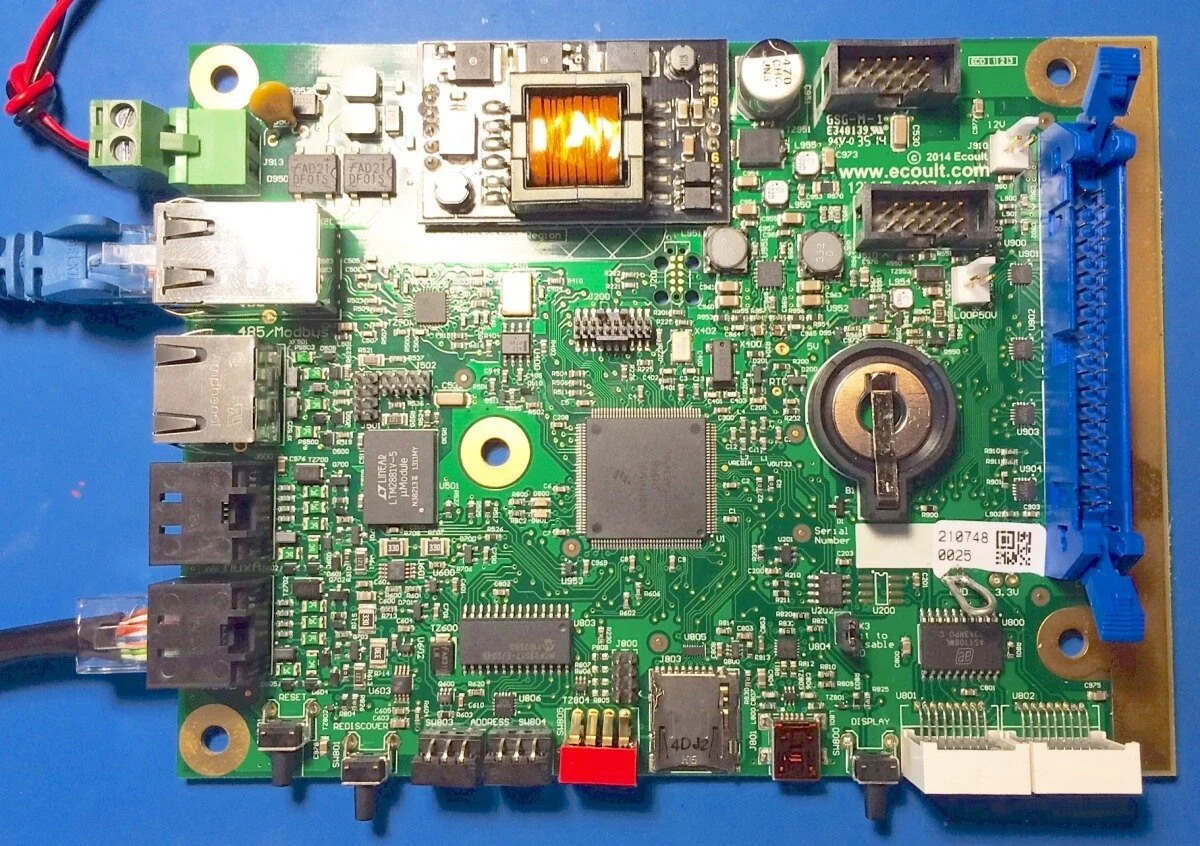

I spent most of 2015 developing this large PCB (right), as well as minor design tweaks and DfM review of all the other PCBs in the Ecoult product stable; classic industrial electronics designed to high-spec high-reliability, low-volume, and very low power consumption. This PCB replaced a PLC and other hacked together prototype modules, and integrated several functions to finalise Ecoult’s ‘UltraFlex’ product, a 20 kW.h, 20 kW, 48V battery energy storage solution brought to market in the same year the Tesla Powerwall was announced.

ARM MCU for Industrial Control

This PCB (left) is classic industrial electronics designed to high-spec high-reliability & low-volume, designed to monitor large quantities of Ecoult UltraBatteries.

For 3 months in 2014 I created the schematic diagram (not routing the PCB), based on the Freescale K60/K66 MCU including interfaces for Ethernet, MODBUS RTU (RS485), CANbus, a string of UltraBatteries, the PCB featured above, uSDcard, USB2, and a complex galvanic isolation scheme. It also worked first spin.

PowerHookah

Kanben, Canada

In 2014 I developed the electronics & firmware for the world’s first breath-controlled battery-powered smoking hookah. Not really my kind of thing, but it is a big thing in some cultures, and the PowerHookah made it safe, clean, and easy, “No Bowls, No coals!” as their promo said! Just pop in a foil capsule of spiced/etc tobacco, ready to burn. Unfortunately Kanben discovered getting into Big Tobacco wasn’t as easy as they’d hoped.

MCU was an Atmel ATmega168, with 3 K-type thermocouple inputs, precision differential air pressure sensor, 3 ceramic/mica-heaters controlled with PWM, 4S2P 18650 LiPo battery pack with BQ24610 charge management IC allowing simultaneous recharge and product usage.

Firmware in Arduino allowed the client to easily modify operational parameters, extract logging & performance data, and reprogram prototypes at will.

OrthoPulse

Clarus Aligners,Egypt

In 2014 I developed the electronics & firmware for a dentist-prescribed Dental Patient product, which halved the amount of time a patient needs to wear aligners.

The MCU was an Atmel AT90USB1286 maintaining RTC functionality, with PWM control over a micromotor with quadrature encoder feedback driving an eccentric weight, DS2502 silicon serial-number, MCP73831 1-cell LiPo charge management IC, and a USB interface for both recharging and ‘License Management’.

Additional to the hardware and core firmware development was a Windows application, and Cloud Service, and additional firmware support, which I subcontracted out. This suite of software and firmware implemented a Patient Compliance Record, and cryptographic Device License Activation scheme. I worked closely with the subcontractor to ensure my client’s requirements were fully met.

The USB interface allowed the prescribing dentist to connect the Pateint’s OrthoPulse via USB and, using the Windows application, retrieve patient usage logs from the device (at their periodic appointments) to verify the Patient’s compliance with their treatment regime. The Windows application also communicated with the Cloud Service to install an updated license-file allowing continued use of the device by the Patient for the prescribed time.

The Cloud Service implemented a full DRM-style License Management System with cryptographic key management. The cryptographic key/license-file system was modern robust crypto, safe from hacking after the first-time factory key installation.